A Little Bit About Castle

Castle is an American woodworking machinery manufacturer that got its start in the 1980’s. All of their machines are made in California, and are finished with the classic “John Deere Green” color as a nod to American ingenuity.

Castle machines allow woodworking shops and businesses to consistently and effectively reach their end product, greatly increasing productivity in joinery, face frames, retail fixtures, drawer boxes, and more.

What is a Face Frame Clamp?

A face frame is a frame that attaches to the front of a cabinet (or to its “guts”) in order to obscure edges and joints and to provide a surface to affix hardware or doors. With the advanced technology of today, face frames are often replaced with edgebanding, however there are still instances where face frames are required.

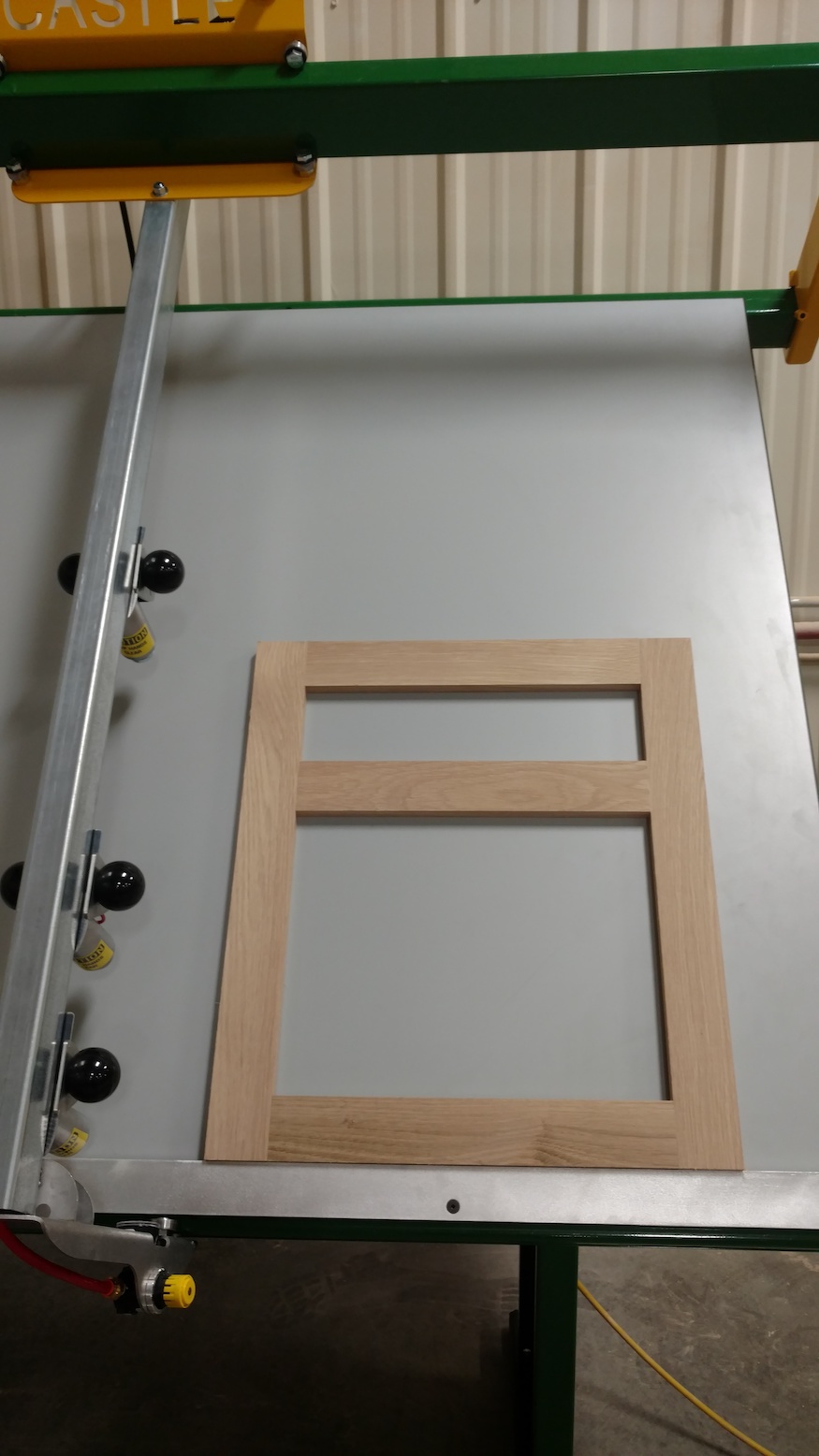

A face frame assembly table is a large table that is usually made of heavy duty materials. It has a sliding arm that is loaded with moveable clamps. These clamps exert pressure downward on to the materials and joints of what will become a face frame for cabinetry.

While the clamps are exerting pressure on the materials for the face frame, the craftsman can screw together and assemble the face frame, ensuring the frame stays secured and true to square during the process.

Basic Parts of a Face Frame Clamp

- Frame – supports the sliding arms, working table, and reduces frame movement when under pressure from the clamps

- Table/Work Surface – This is an angled surface that supports the materials that will become the face frame. The unique angle of the table helps make the process easier for the craftsman.

- Sliding Arms – The sliding arms hold and position the clamps over the joints

- Clamps – this is what exerts the pressure onto the materials laid up to become a face frame.

Our Castle Face Frame Clamp

A current residential project we are working on contains a large amount of face frame work and provoked some thought into increasing our efficiency as a shop in producing a large amount of face frames.

Building and assembling face frames is not by any means a new skill for our craftsmen at D.P. Juza Woods & Fixtures, but we felt having a tool specifically designed for the process would not only increase our efficiency in the shop, but also help us to provide our clients with the most accurately constructed product possible.

Our new Castle AT-Race 8 face frame clamp arrived on the shop floor and immediately upon unpacking, the heft and construction of its parts gave us an inkling that we would get a lot of use out of this machine in the future.

Our face frame clamp is equipped with a 4′ x 8′ support table, one clamping arm that can move from side to side along the length of the table, and a square bar on the left side of the table. The clamping arm has three separate clamps on it that can be adjusted vertically to fit whatever size face frame we need to make.

So far, what we love most about the machine is that the beam and clamping arm are actually elevated above the support table. This opens up space at the top of the table which allows us to place larger materials on the machine that require more vertical space.

Tune into the D.P. Juza Woods & Fixtures blog each week for an inside look at the machines that power our Shell Lake woodworking shop. For a closer look at the quality of our work, we invite you to view our recently completed pieces in our project gallery.