A Little Bit About Shopsabre

Shopsabre is an American company that produces an array of CNC routers and CNC plasmas that are manufactured in Elko, Minnesota. In 2012, Shopsabre released one the most advanced and powerful machines on the market for under $100,000 – the Shopsabre IS CNC router.

The IS model is the most robust with bigger parts, motors, and twice as much power on its drive axes than the next model down. It also has a 7.5 KW HSD spindle that enables us to cut a at feed rate of 2100 IPM.

What is a CNC Router?

CNC stands for Computer Numerical Control. A CNC router is a machine that uses computer software and control to drive a mechanical cutting system. Some of the materials the CNC routers can cut include composits, aluminum, steel, foam, plastic, and in our case, wood.

These machines cut in three axes, typically labeled as X, Y, and Z, and have the capability to cut all three axes in perfect unison. What does this mean? It means this machine allows for better quality, accuracy and precision than any human could ever replicate.

Basic Parts of a CNC Router

The Control System and Computer are the brains of the machine. They tell the moving and cutting parts where to go, what to do, and when to do it.

The spindle is what cuts the material, similar to a standard wood router. The spindle on the IS 510 can spin anywhere between 8,000 and 30,000 rpm. The bed is what supports the materials that need to be cut.

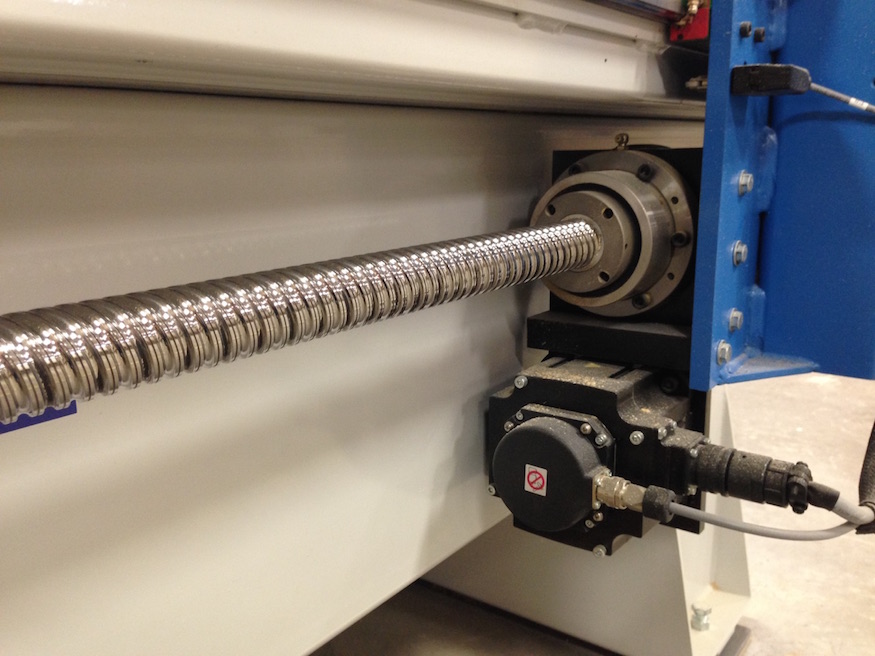

There are two commonly used types of beds on a CNC router – a T slot which utilizes and insert in an MDF table where clamps aid in holding the materials being cut, and the vacuum table where a spoil board and work piece are held to the table utilizing a vacuum pump. The Linear Drive System is what moves the spindle. Each axis operates with its own, separate linear drive system.

The Role of Our Shopsabre at D.P. Juza Woods & Fixtures

Our Shopsabre IS 510 is primarily used for nested based manufacturing.

Previously, we cut all of our parts on a panel saw and then machined them on a point to point machine. The IS 510 provides the best yield of material possible and parts come off the machine ready to edge band and assemble.

Though many will argue that someone who cuts parts or shapes into wood with a CNC machine is not a craftsman, proficiency in running one requires more skill, knowledge, and creativity than most people will realize. If the operater sets the feed rate of the machine too low, the wood may burn, and if it is cut too deep, the router bit may break. The operater also needs to know how to select the proper bit for the project.

Our response to those arguments: anyone who believes operating a CNC does not require skill or craftsmanship should try for themselves. They will soon find it requires more skill than most woodworking tools. As far as the end product goes; well, as for us – we’ll settle for perfect.

Contact us to get started on a custom woodworking project for your home, office, or retail space. Don’t worry, we’ll operate the CNC.